Revolutionary Emirati Project is Latest in UAE’s Relentless Efforts to Strengthen Healthcare Sector to Meet Challenges of COVID-19 Pandemic

Khalfan Belhoul, CEO of Dubai Future Foundation (DFF), confirmed the launch of an innovative mechanical ventilator prototype, M061, comes in line with its sustained efforts to support frontline healthcare workers in their efforts to safeguard the lives of those affected by COVID-19.

Belhoul said that Project M061 was initiated and implemented under the directives of His Highness Sheikh Hamdan bin Mohammed bin Rashid Al Maktoum, Crown Prince of Dubai and Chairman of the Executive Council of Dubai, and Chairman of the Board of Trustees of the Dubai Future Foundation, to address the urgent need for large numbers of mechanical ventilators that play a crucial role in treating patients with severe symptoms of COVID-19.

In an earlier media statement, His Highness noted that the development of the ventilator is part of the country’s efforts to deploy breakthrough technologies in the fight against COVID-19 and to enhance its healthcare capabilities.

Within the context of the intense pressure global supply chains face as a result of restrictions in different countries, the M061 Project serves as a response to calls for local ventilator production to meet the needs of the UAE population.

This crucial healthcare project is a partnership between Dubai Future Foundation, Office of Minister of State for Artificial Intelligence, Dubai COVID-19 Command and Control Centre, Ministry of Health and Prevention, Dubai Health Authority, Mohammed Bin Rashid University of Medicine and Health Sciences, as well as government agencies, research centers and international institutions.

The Dubai Future Foundation assembled an interdisciplinary team of local and international engineers, programmers, industry experts and healthcare specialists to develop the robust and rapid prototype mechanical ventilator that would also contribute to the international open source network that has emerged to tackle the device shortage.

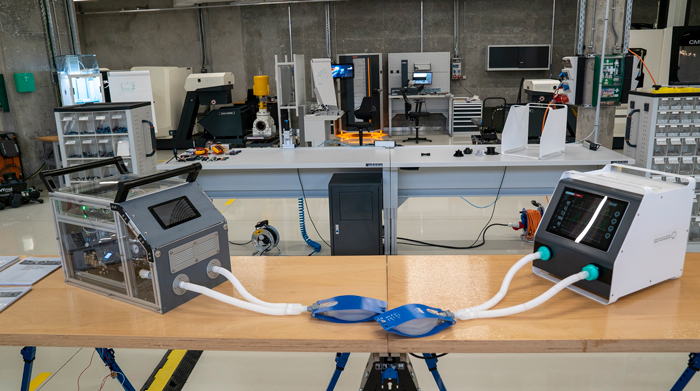

Over an eight-week period, the project team worked relentlessly to design and build the M061 ventilator system as a modular and scalable prototype, relying on interchangeable components that are easy to source and integrate, in an effort to circumvent the world-wide scarcity of crucial medical supplies.

By closely studying existing ventilator designs, the team identified functionality and durability as two key elements that would help make a difference and define the M061 ventilator. The team designed and tested prototype medical ventilators systems that could provide oxygen to patients for longer periods and efficiently adapt to changes in vital indicators such as blood pressure, heart rate and temperature.

The M061 prototype has been designed to address the individual needs of patients by delivering multiple modes of ventilation in the pressure and volume mode families, along with further assistive and supportive functions, based on the patient’s breathing capacity. The prototype, which consists of a mechanical airway made of tubes, fitted with various valves, sensors and filters, is capable of providing invasive and non-invasive mechanical respiratory assistance with the aim of sustaining raspatory support for both short- and long-term periods. Incorporating a custom printed circuit board (PCB), the prototype facilitates easy interface with various types of I/O (input/output) devices.

A typical ventilation process is a cycle of precisely controlled inhalation and exhalation phases. During the inhalation phase, the ventilator takes in air and compressed oxygen, and blends them in a mixing chamber to achieve the required oxygen concentration for the selected ventilation mode – normally between 21 percent and 100 percent. This mixture is then released into the patient’s lungs according to a specific ventilation profile.

Ventilation profiles are of two types – pressure-controlled profiles that focus on precisely controlling the pressure during inhalation to avoid causing a ventilator associated lung injury (VALI), and volume-controlled profiles that attempt to deliver the required volume precisely.

During the development process, the team followed standard professional engineering practices to ensure that the ventilator adhered to the highest quality standards and received input from ventilator specialists currently treating COVID19 patients. The Project M061 team followed the recently established Rapidly Manufactured Ventilator System (RMVS) standards outlined by the Medicines and Healthcare products Regulatory Agency (MHRA) in the UK.

The M061 prototype has been specifically designed to address the unique circumstances of the current pandemic and alleviate the pressure on healthcare systems during the crisis. The prototype is intended to support, rather than replace, existing hospital ventilators that have broader medical applications and are designed to last for significantly longer durations.

The team plans to execute a rigorous testing cycle, under the supervision of pulmonary specialists and clinicians in hospitals in Dubai, to ensure that the ventilator system complies with established standards and meets international requirements.

The Project M061 team includes: Khalifa Al Qama, Head of Dubai Future Labs and project lead, Saqer Bin Ghalib, Director of Artificial Intelligence Office, Dr Tarek Taha, Robotics Lab Lead, Rashid Al Suwaidi, Software Engineer, Majed Al Khatib, Lab Technician, Hamad Mohamed, Software Engineer, Layth Mahdi, Senior Robotics Researcher, Alexander Spies, Senior Integration Manager, Julian Ferling, Deputy Integration Manager, Mohamed Alzahmi, Software Engineer and Maryam Buhumaid, Foresight Analyst.